Production Process

Raw blank prepared for metal spinning.

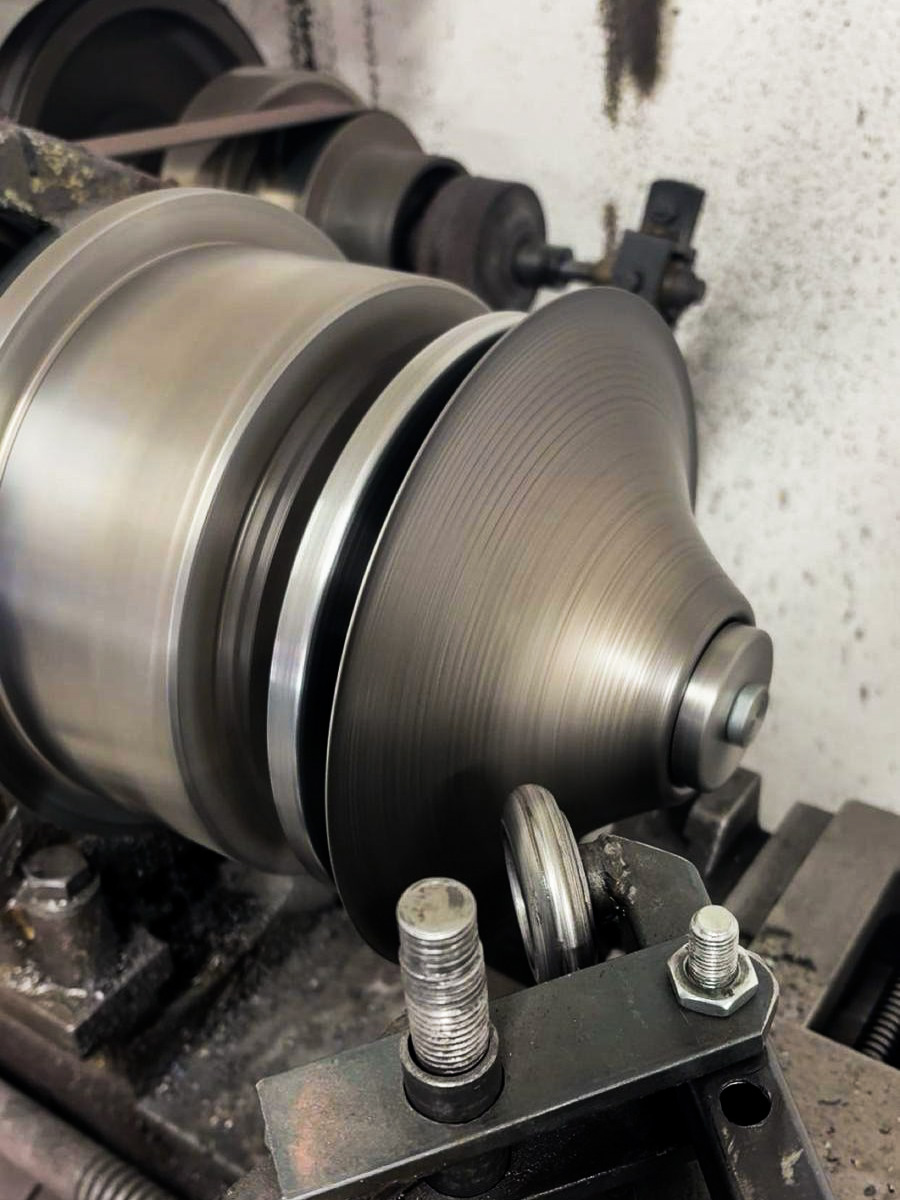

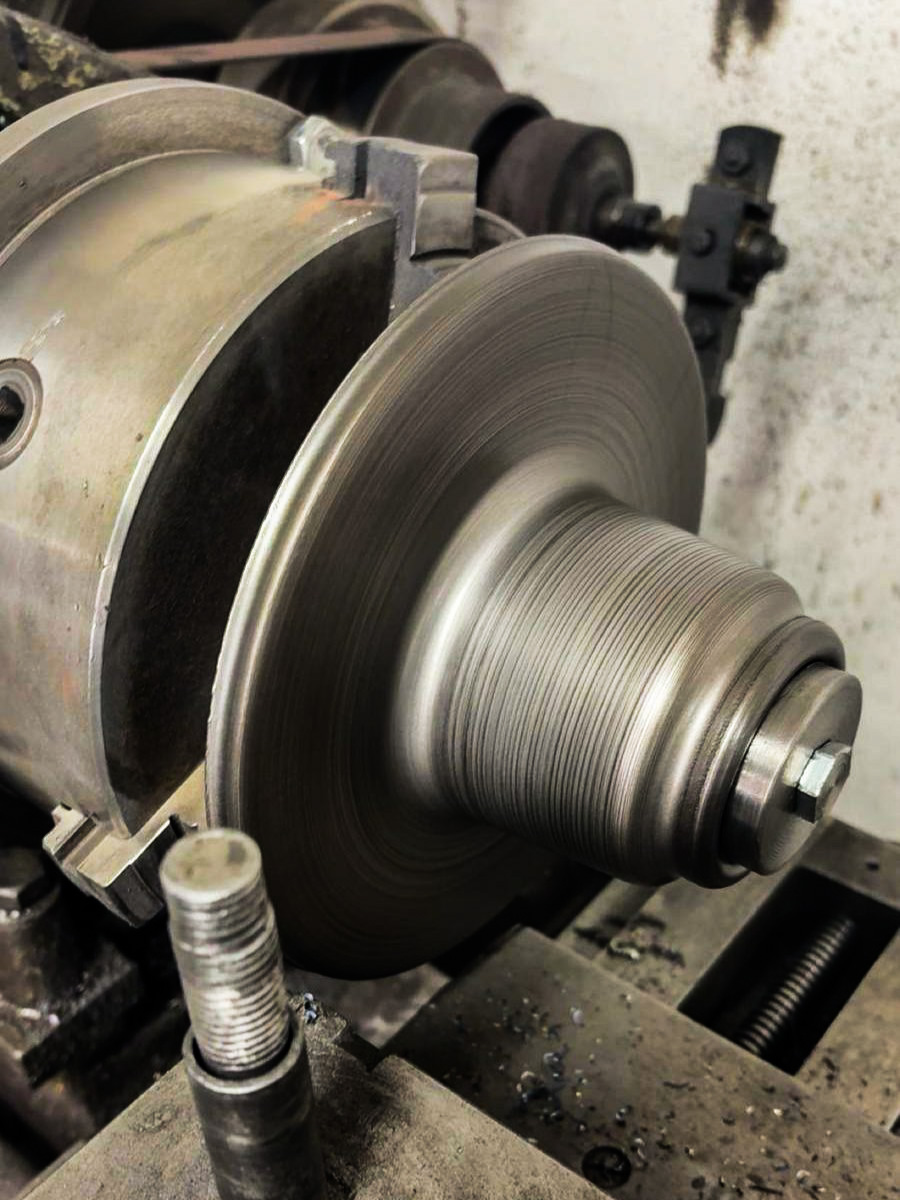

Pre-stretching the material before final pressing.

Shaping the material to precise dimensions and curve.

Manual sanding in preparation for polishing.

Polished blanks ready for drilling and subsequent chroming.

Test fitting of the emblem before chroming and riveting.